We can tailor-make the shape and type of closure, colour, diameter and height of the neck, surface finish, coupling and material used.

Every feature and detail of the product can be customised to achieve the desired result, considering the aesthetic and functional objectives, as well as the reference sector (cosmetics, personal care, food, parapharmaceuticals).

Thanks to this tailor-made approach, we develop new dispensing systems based on customer requirements. Our team of professionals “GIFLOR LAB” offers engineering and design skills to support customers throughout the process and create unique and functional packaging as result of the in-depth market analysis.

We can create prototypes and tooling for molding custom plastic caps in a highly competitive lead time, relying on a global network of suppliers who provide us with only high quality materials. Furthermore, we believe in the value of our customers’ ideas, which we defend and protect with utmost confidentiality.

<!–The process for creating prototypes for moulding custom plastic caps involves several steps. After a briefing with the customer, during which we are provided with the necessary information to develop the design, we examine the latest trends in the sector through in-depth market research.

From this analysis we can design the prototype, which is carefully examined by our engineers and, subsequently, the design team.–>

Custom made

The process of creating prototypes and tooling for molding custom plastic caps involves several steps. After the briefing with the client, in which we gather the necessary information to develop the design, we study the latest trends in the sector through particularly accurate market research. This in-depth analysis allows GIFLOR LAB to develop the prototype, which must then be submitted to the scrutiny of our engineers and, later, the design team. Throughout the process, the focus is always on the needs of our customers, from whom we receive constant feedback, with regular reviews and checks. Once the customer's approval is obtained, we quickly create customized equipment for a quick go-to-market of the product. We consider the development of custom plastic caps almost a form of craftsmanship, so our work ends only when the customer is 100% satisfied with the product we have created.

-

STEP 1

Briefing with the client

-

STEP 2

In-depth research

-

STEP 3

Development of ideas

-

STEP 4

Creative definition

-

STEP 5

Project development

-

STEP 6

Engineering

-

STEP 7

Design validation

-

STEP 8

Marketing

-

STEP 9

Execution and evolution

-

STEP 10

Satisfied customer

QUICK PROTOTYPING

DEVELOPING INDUSTRIAL MOLDS

PROFESSIONAL TEAM

CONSTANT UPDATE

GLOBAL NETWORK OF SUPPLIERS

MARKET REQUIREMENT ANALYSIS

IDEAS PROTECTION

Personalize

A custom made product must not only comply with specific technical characteristics, but also be able to best represent the spirit of the brand. Giflor fully embraces this philosophy, which is why every detail of our caps can be customized. With over 350 colors available with different aesthetic effects (glossy, matte, semitransparent, pearly, glittered) and post-production treatments (metallization and hot stamping), the customer can choose the color combination and, if necessary, even create a new one which best fits the personality of the company and the emotional experience it intends to generate. The companies who choose Giflor for molding custom plastic caps can also request the application of their logo on the product, both in bas-relief and in high relief.

Throughout the process, the focus is always on the needs of the customer, who provides constant feedback through regular reviews and checks. We consider the moulding of custom plastic caps as a form of craftsmanship, so our work ends only when the customer is 100% satisfied with the product we have created.

Request information Tailor Made

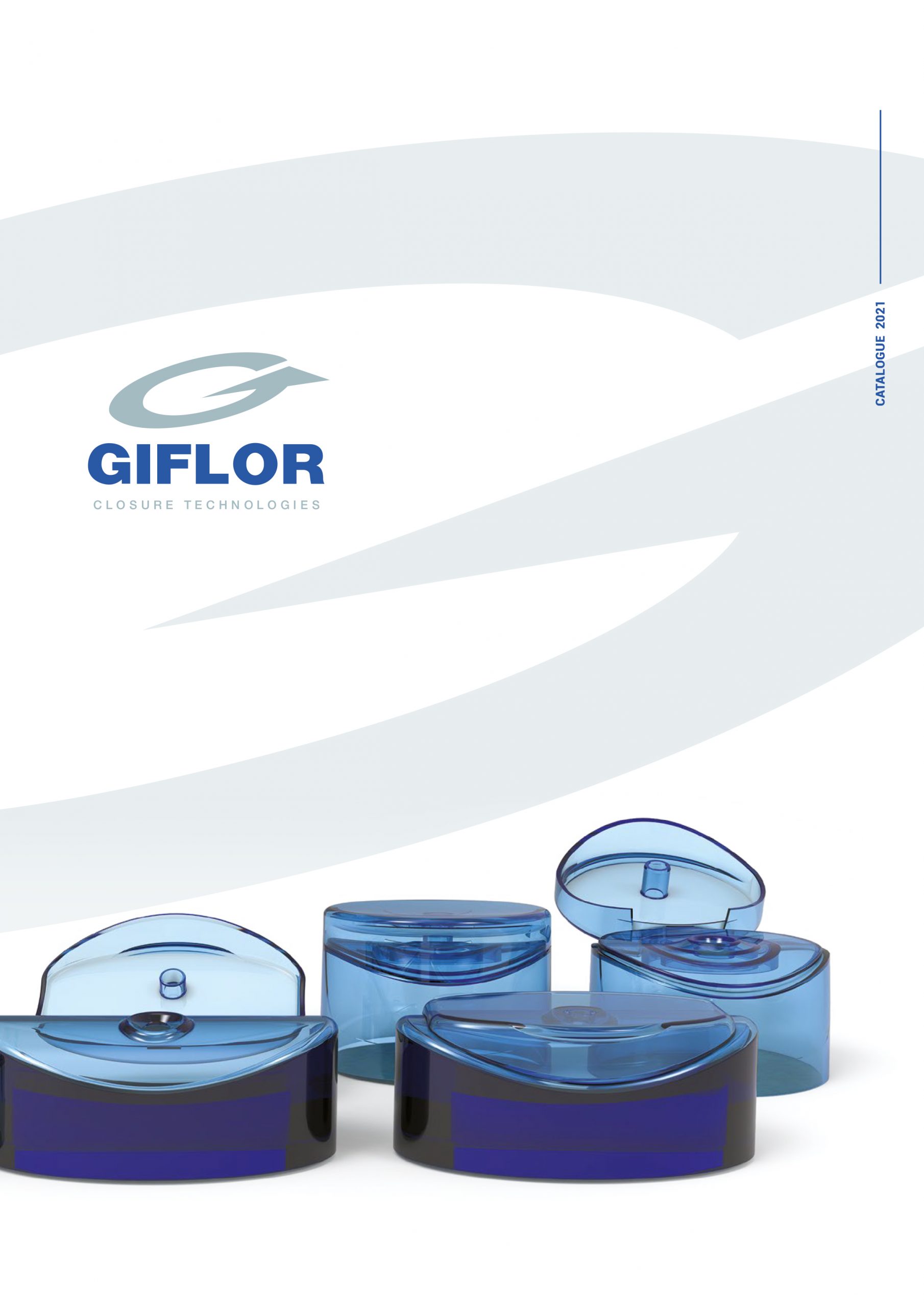

Download the 2024 Product Map

Discover all the solutions available to you by consulting the latest edition of our Product Map.

DOWNLOAD PDF

Request Catalogue

Contacts

One of our consultants is at your disposal to satisfy your requests and offer you all the necessary assistance

CONTACT US